-

Choose your category:

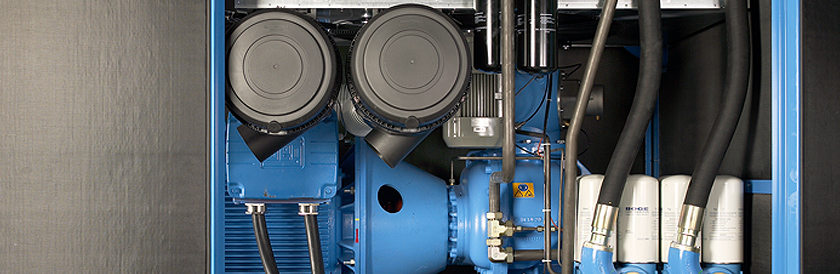

Air Compression

The Masters Air Compressor Line is based on a full line of mineral oil and synthetic compressor oils that are formulated with the highest quality basefluids and additives to optimized lubricant life. The diverse family of fluids are designed to provide the customer with service life and price point choices that will meet any application or conversion need. Fluid life for this series of fluids can range from 2,000 hours to 16,000+ hours.

AVAILABLE FLUID CHEMISTRIES:

- Group II and III Mineral Oil

- PAO

- PAO Blends

- Polyol Ester

- PAG / Ester Blends

Typical Industrial Applications: Rotary Screw Compressors, Rotary Vane Compressors, Reciprocating Compressors, Centrifugal Compressors, Vacuum Pumps.

Download the Masters lubricant recommendation form here (PDF)

Barrier Fluids

Masters Barrier Fluids are formulated with best available polyalphaolefin (PAO) base fluids to ensure fluidity at low temperatures and oxidative stability at high temperatures. These barrier fluids will lubricate and cool the seal face of double and tandem mechanical seals.

These fluids do not contain additives or impurities that may poison or negatively affect process fluids or catalysts. These barrier fluids are not for use with EPDM or EPR elastomers. They are compatible with most other commonly used seal materials.

Typical Industrial Applications: Double mechanical seal and liquid ring.

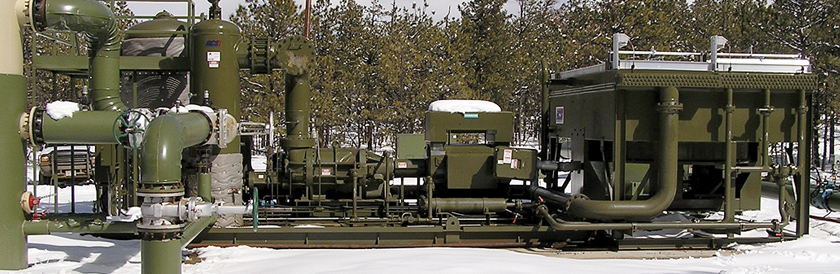

Hyrdrocarbon/Process Gas

Masters Process & Hydrocarbon Gas Fluids offer fluid options for almost any gas stream and compressor conditions. Offerings include specific formulated fluids for process gas, inert gas, reactive gas and all hydrocarbon. All fluid chemistries are available to ensure the correct fluid characteristics are recommended for these critical applications.

Typical Industrial Applications: Rotary Screw Compressors, Rotary Vane Compressors and Reciprocating Compressors.

Hydrocarbon gas fluids are recommended using a proprietary dilution program to determine lubricant viscosity loss as well as a complete review of the gas stream and compressor conditions. After this analysis is completed the best fluid is recommended for each specific application. Download the Masters lubricant recommendation form here (PDF)

Foodgrade

Masters Food Grade Approved Fluids are formulated with the highest quality white mineral oil and polyalphaolefin (PAO) base oils to ensure optimal performance. Specific applications include air compressor, CO2, inert gases, hydraulic, and gear fluids. Life ranges depending on application can range from 2,000 hours to 8,000 hours.

Typical Industrial Applications: Rotary Screw Compressors, Rotary Vane Compressors, Reciprocating Compressors, Vacuum Pump, Hydraulic and Gear.

Refrigeration

The Masters Refrigeration Fluids are complimented by a comprehensive line of mineral oil and synthetic compressor oils. Available fluids are for specific applications which include ammonia, CO2, Hydrocarbons, HFC and HCFC refrigerants.

The diverse family of fluids that includes Paraffinic, Naphthenic mineral oils, PAO, PAG, Ester and Alkyl Benzene products are designed to provide the customer with assurance of meeting all OEM requirements and all required industry standards.

Typical Industrial Applications: Rotary Screw Compressors, Reciprocating Compressors and Scroll.

Download the Masters lubricant recommendation form here (PDF)

Gear Lubricants

Masters Gear Fluids consist of mineral oil and full synthetic options that have been formulated with premium mineral oil, polyalphaolefin (PAO) and polyalkylene glycol (PAG) base fluids for all gear systems requiring a wide range of formulating needs.

These fluids have been designed to provide proper lubrication under differing load and speed conditions such as hydrodynamic, mild boundary lubrication and boundary lubrication conditions. Product line options also include fluids for applications containing soft metals such as bronze, brass and copper.

Typical Industrial Gear Applications: Worm, Bevel, Spur, Helical and Hypoid.